Stay Connected

Sign up to receive news, updates, exclusive offers and more!

336-885-2265 | info@aldenhomefurniture.com

© 2023 Alden Home, LLC. All Rights Reserved. Site by WDW

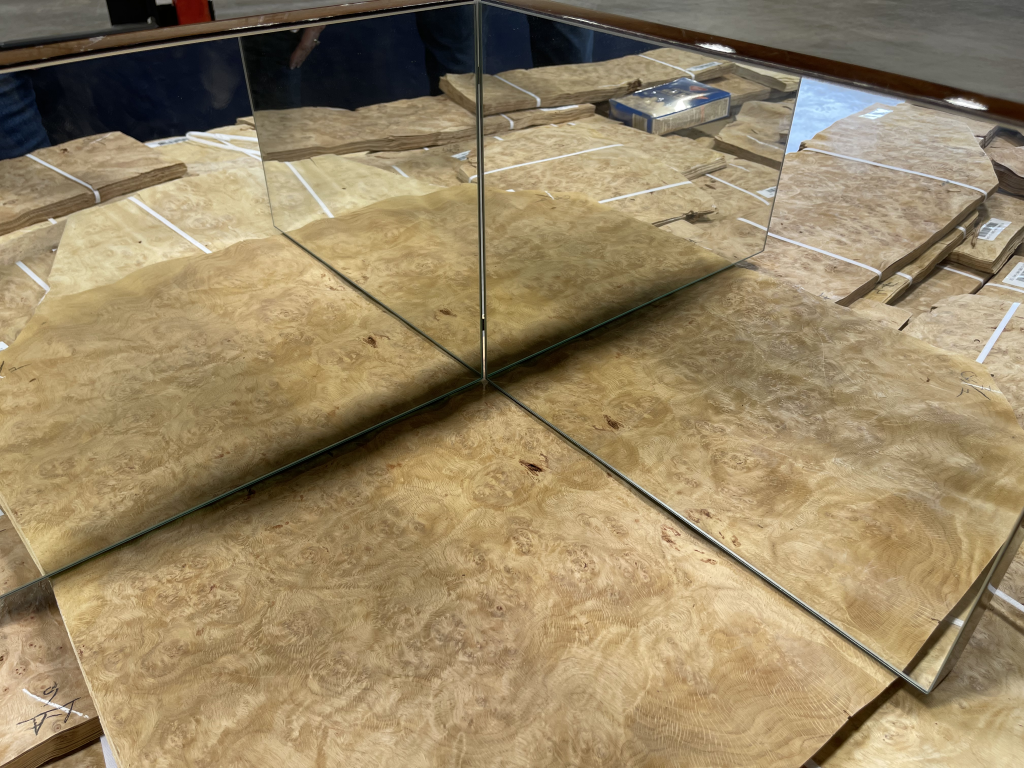

PLEASE NOTE: Images shown on our website are for illustration only and may include special upholstery or finishes which may or may not be currently available and which, if available, may incur upcharges plus Special Order fabric or leather costs.